WHAT DO WE DO

Since 2014 we have specialized in providing production-level hydrographic decorating, also known as hydro dipping services to the OEM, Automotive, Marine, and Outdoor industries. Our process ensures a high-quality, durable final product. Whether you need 1 or 10,000 pieces, we can design a custom process and application to fit your needs. Some of the items we apply the hydro-dipping process to include outdoor equipment (camo dipping), automotive trim and interiors, furniture, aftermarket performance parts, and various other applications. We offer several coating options including Hydrographics (hydro dipping), custom paint, and powder coating.

Precision Hydrographics & Coatings mission is to provide a custom aspect to virtually any substrate in any application you choose. At Precision Hydrographics & Coatings, we specialize in commercial OEM production work, high volume - large capacity projects for the OEM Automotive, Healthcare, Marine, and Outdoors Enthusiast industries.We offer one of a kind, unique and individualized products for each unique customers needs and applications. We give each project the highest attention to detail and guarantee quality control on every product leaving our facility. We know that your business is important to you, and it is just as important to us. We guarantee not only our products, but also the results and expectations of you as our client on every project that we work on.

OEM Production Processing

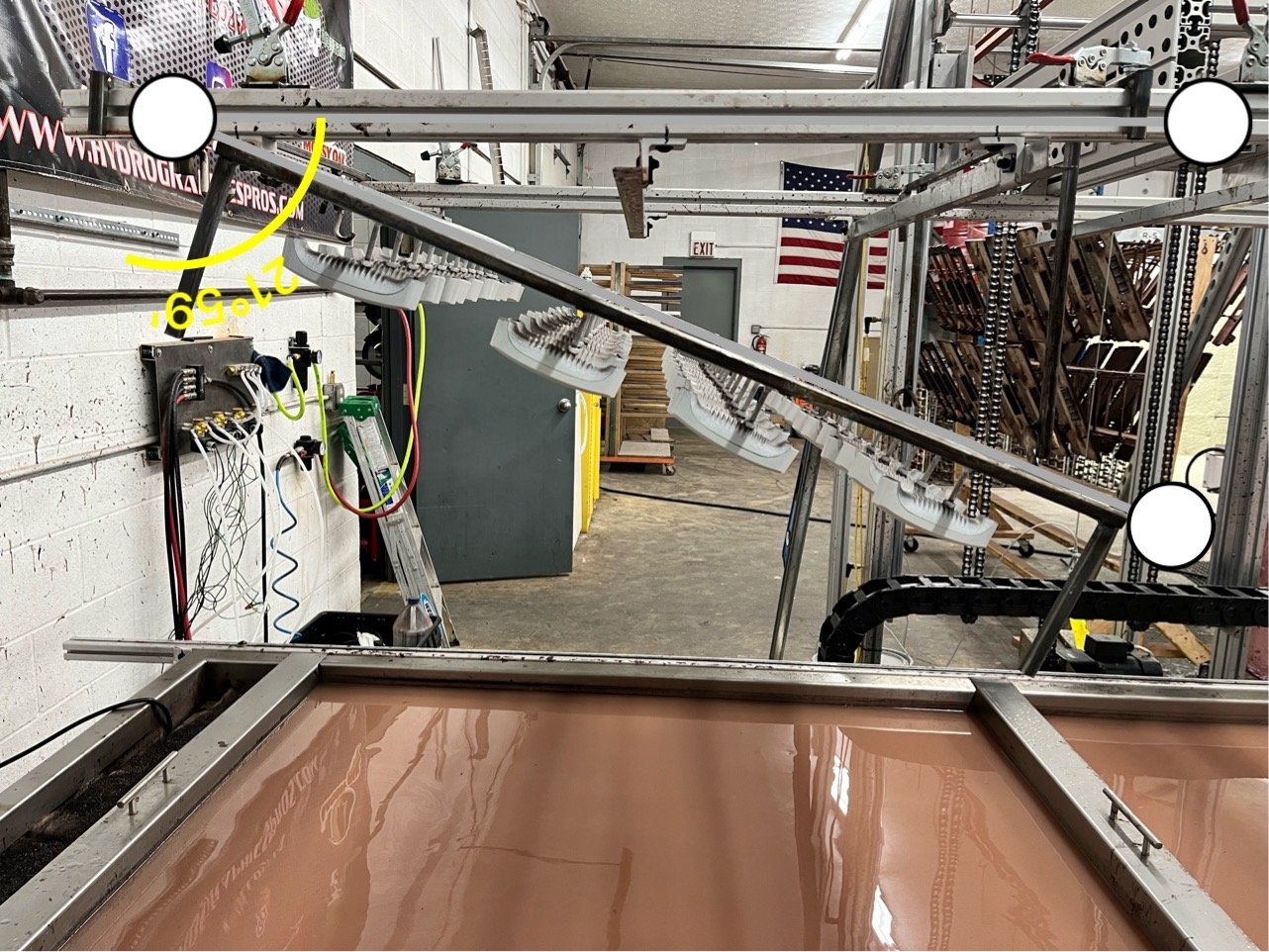

Our state of the art facility allows us to produce precise and repeatable results ensuring the highest quality control standards in the industry. We specialize in high-volume, large capacity projects to meet any and all needs of our clients. Our professionally trained staff is dedicated to making sure that each piece that leaves our shop meets 100% quality control standards set by you, the client. Our fully automated process guarantees repeatable accuracy and precision while minimizing variables for inaccuracies. Using our automated system, we are able to lower cost, turn around time, lead time, and ultimately provide a cheaper, and better product for your end users and customers regardless of the situation.

Custom Hydrographic Services

We are a production level facility that processes thousands of parts each week. We have a dedicated custom job department totally separate from our production line to facilitate the needs of our customers that just want to get their personal items dipped. Our team of professionals dedicated to custom work have years of experience with production as well as very complex, one-off piece work which enables us to provide accurate results with minimal testing time for a shorter lead time than a large production job. Gun stocks, automotive parts, motorcycles, electronics, etc. are some of the types of parts we process each week for our walk in clients. Click here for a free quote or give us a call!

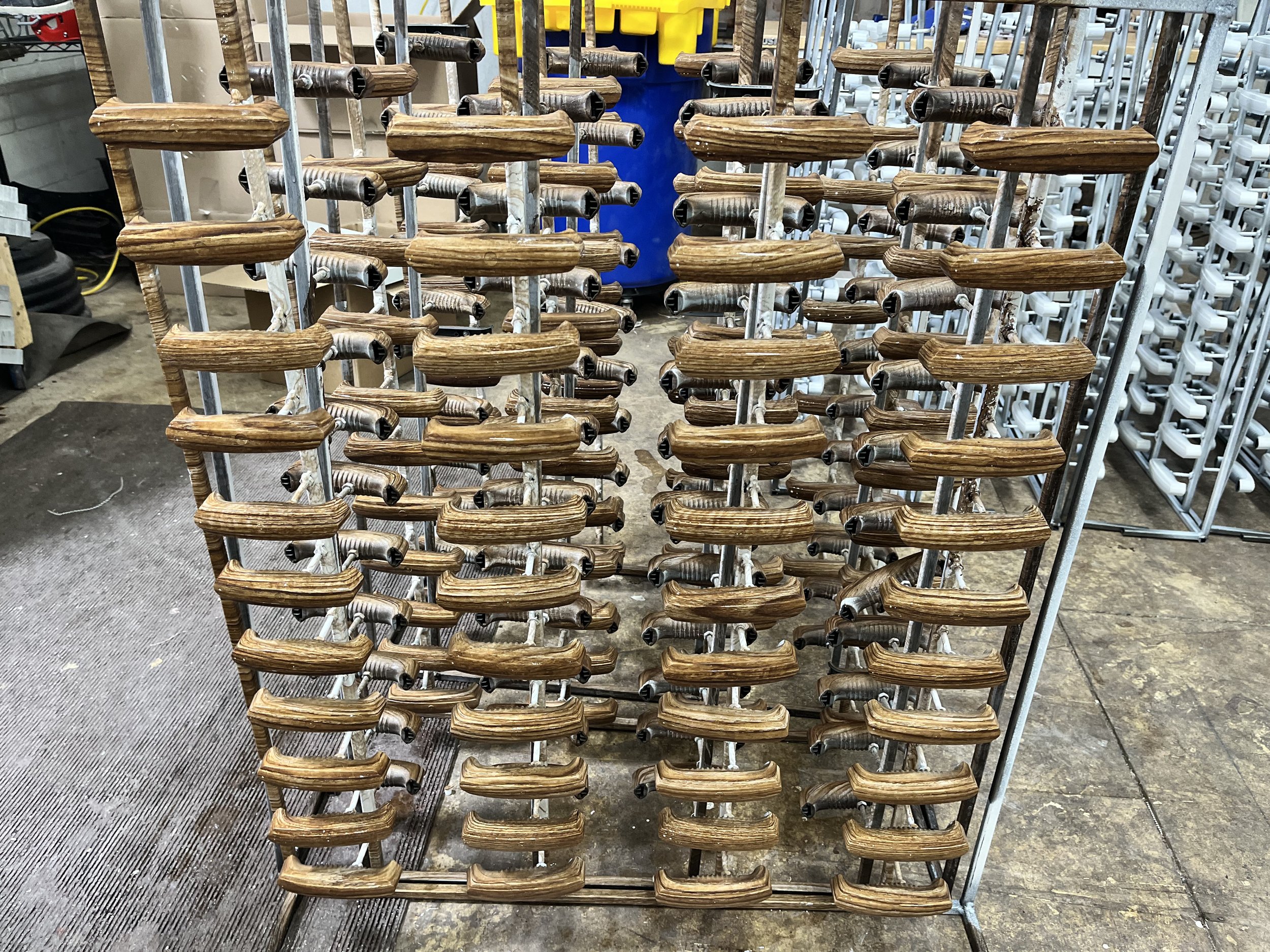

The Hydrographic Process

The water transfer (or hydro dipping) process begins by placing your parts onto custom built fixtures. These may be provided or fabricated by Mid-Ohio Hydro. We have developed custom fixtures and tooling for many of our clients. We use only the highest-quality coatings to ensure years of durability. Our paints and clear coats were designed specifically for this process and will provide a beautiful, long-lasting gloss or matte finish. Your choice of patterns can include Realtree and Mossy Oak Camouflage, wood grain, marble and stone, carbon fiber, or even your own custom designed pattern!

Prep

Once we receive your product, we will clean it to remove any waxes, oiles, residues, etc. This includes removing any oil from the molding process such as release agents. Some parts may require flame treatment or compound treatment to remove oils, residues, etc. Our process ensures the base paint and coating have a proper adhesion and bond to the product allowing for a high contrast, rich, durable finish that will last.

Base Color

Most product substrates and materials require a base paint to be applied. We use state of the art, purpose designed paint specifically engineered for our process. Depending on the substrate and pattern of choice, we will paint your product as part of the initial first steps prior to the water transfer printing or hydro dipping process.

Graphic Transfer

We partner and source our materials (also known as patterns and films) from several different manufacturers and retailers around the world giving us an almost endless selection of select brands such as Mossy Oak, Kryptek, True Timber, and several others. We also have a unique capacity and capability to design custom patterns and films in house for completely customized special projects. Our fully automated system produces an unparalleled finish that can be duplicated thousands of times without the factor of human error.

Clear Coat Protection

All products are finished and completed with a unique, durable, and long lasting protective clear coat finish. We offer a variety of clear coat finishes including matte/flat, satin, semi gloss, and high gloss. Special finishes such as a textured or rubberized finish is also used on specific applications and processes.

Precision Hydrographics & Coatings Staff is Professionally Trained and Certified

Precision Hydrographics & Coatings employees are factory trained and certified on all aspects of our process to ensure the quality control standards are met or exceeded on each project we work on

Our Location:

31 Waterloo Rd,

Mogador, OH 44260

Business Hours:

M-F 7:30 - 5:30

Phone Number:

(330) 426-8113