WHAT DO WE DO

Since 2014 we have specialized in providing production-level powder coating, ceramic coating, and water transfer printing, also known as hydro dipping services to the OEM, Automotive, Marine, and Outdoor industries. Our process ensures a high-quality, durable final product. Whether you need 1 or 10,000 pieces, we can design and taylor a process and application to fit your needs.

Precision Hydrographics & Coatings mission is to provide a proven and tested coating aspect to virtually any substrate in any application you choose. At Precision Hydrographics & Coatings, we specialize in commercial OEM production work, high volume - large capacity projects for the OEM Automotive, Healthcare, Marine, and Outdoors Enthusiast industries.We offer one of a kind, unique and individualized products for each unique customers needs and applications. We give each project the highest attention to detail and guarantee quality control on every product leaving our facility. We know that your business is important to you, and it is just as important to us. We guarantee not only our products, but also the results and expectations of you as our customer on every project that we work on.

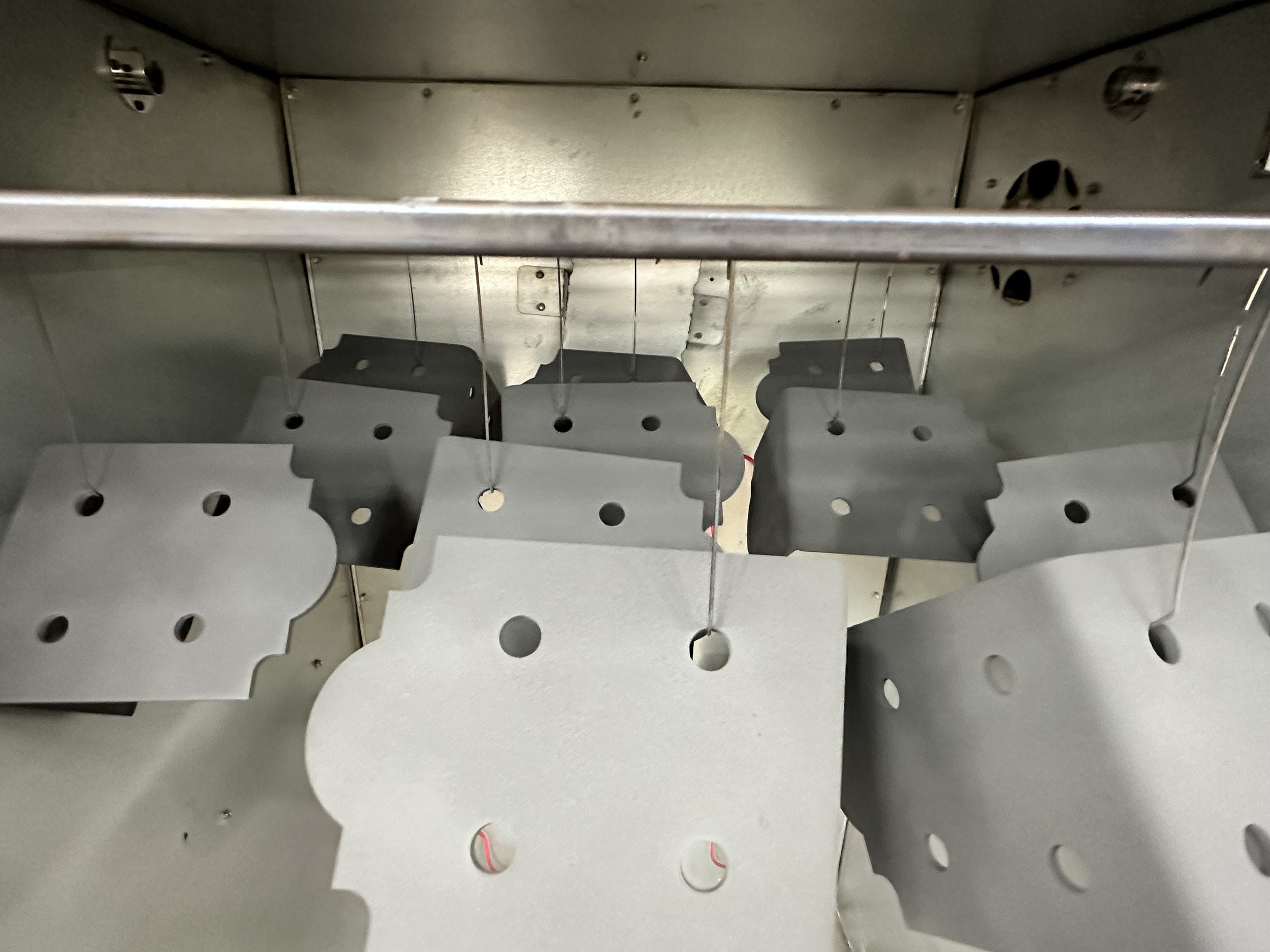

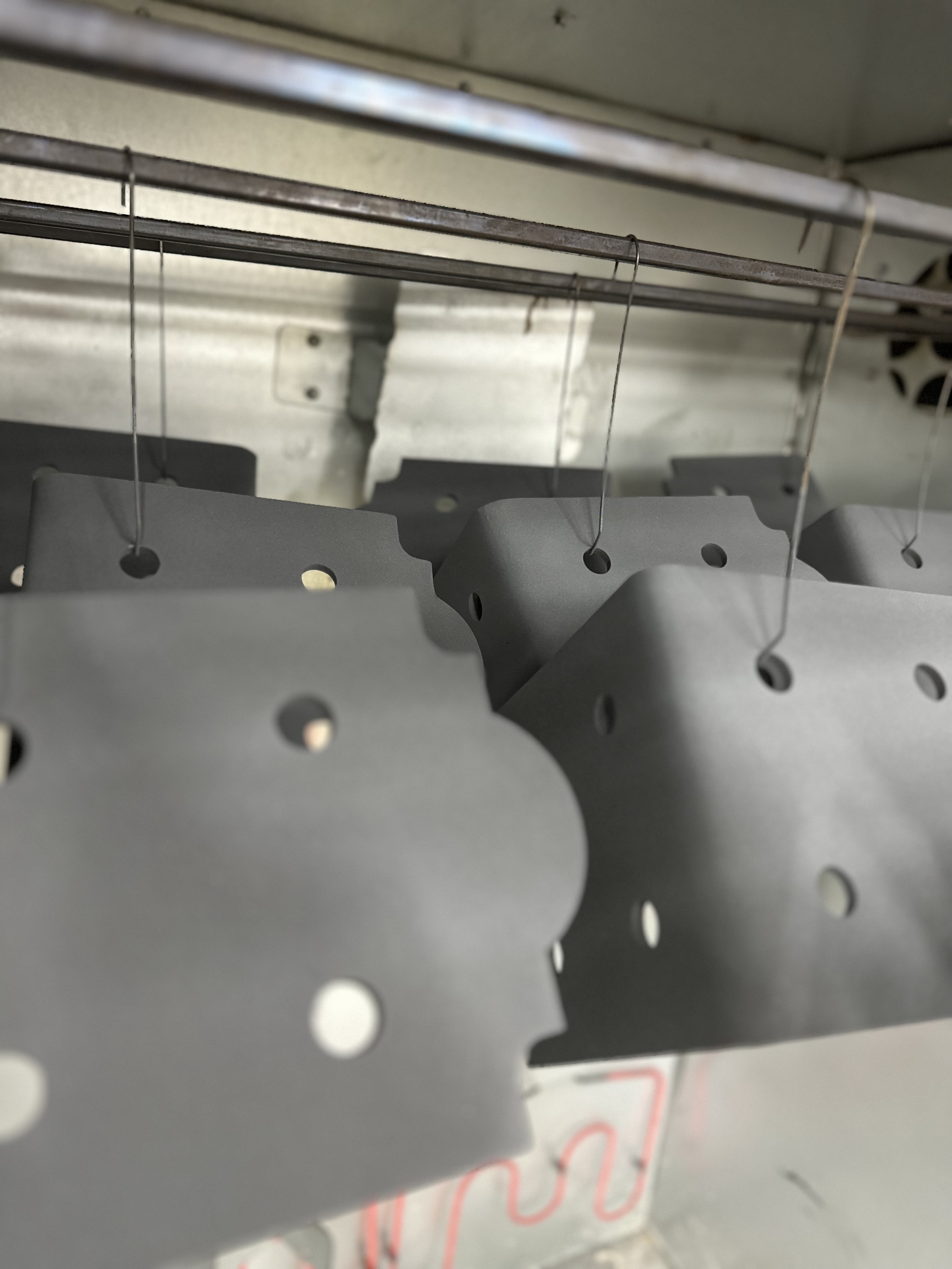

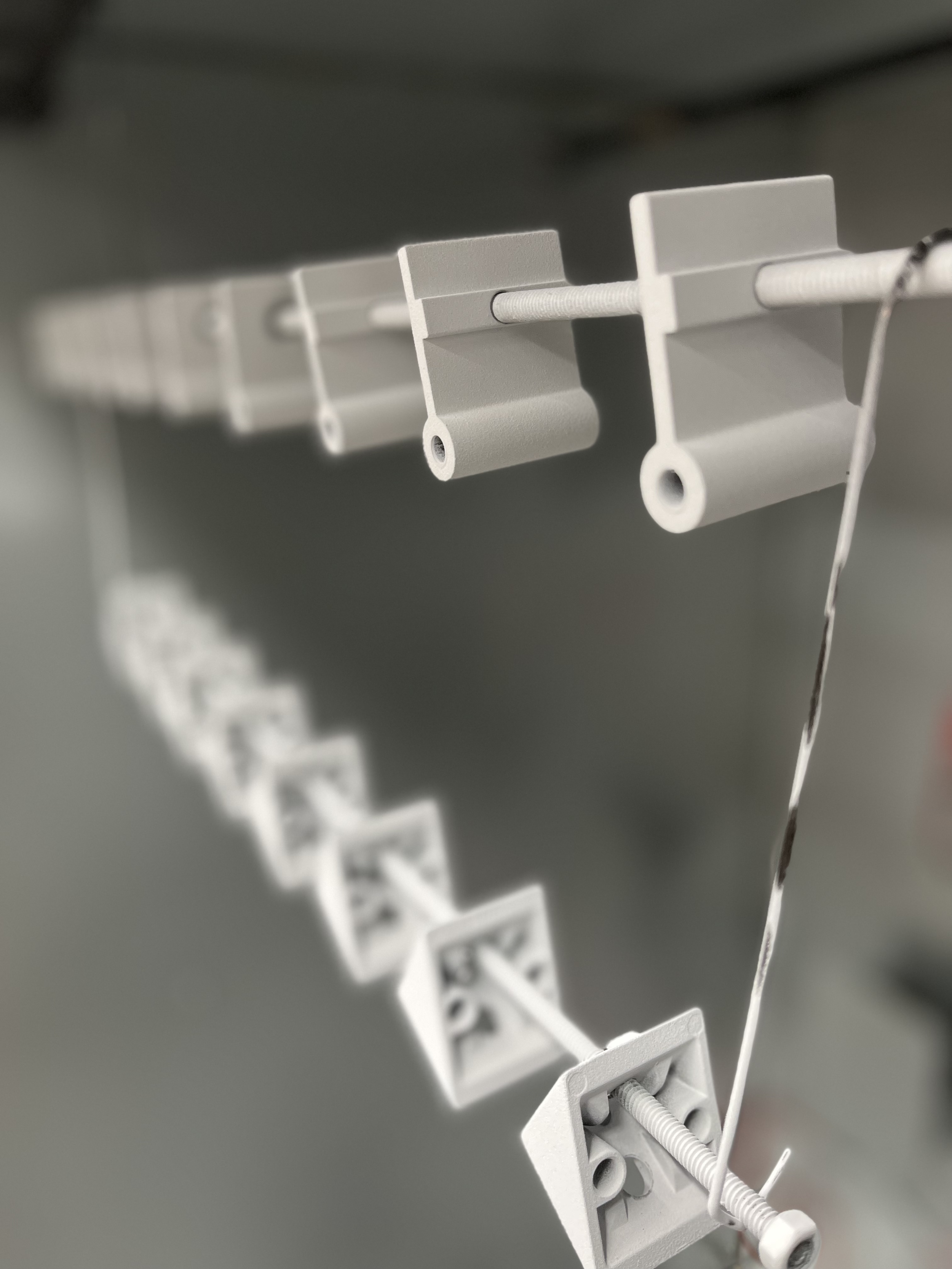

OEM Production Powder Coating Processing

Our state of the art facility allows us to produce precise and repeatable results ensuring the highest quality control standards in the industry. We specialize in high-volume, large capacity projects to meet any and all needs of our clients. Our professionally trained staff is dedicated to making sure that each piece that leaves our shop meets 100% quality control standards set by you, the client. Our fully automated process guarantees repeatable accuracy and precision while minimizing variables for inaccuracies. Using our automated system, we are able to lower cost, turn around time, lead time, and ultimately provide a cheaper, and better product for your end users and customers regardless of the situation.

Capacities

500 sq.ft. indoor media blasting room

unlimited space outdoor blasting area

various blast medias available for any project scope and requirements

5x5x6 electric oven for small parts (batch oven)

30x12x10 gas fired oven for large parts (large batch oven)

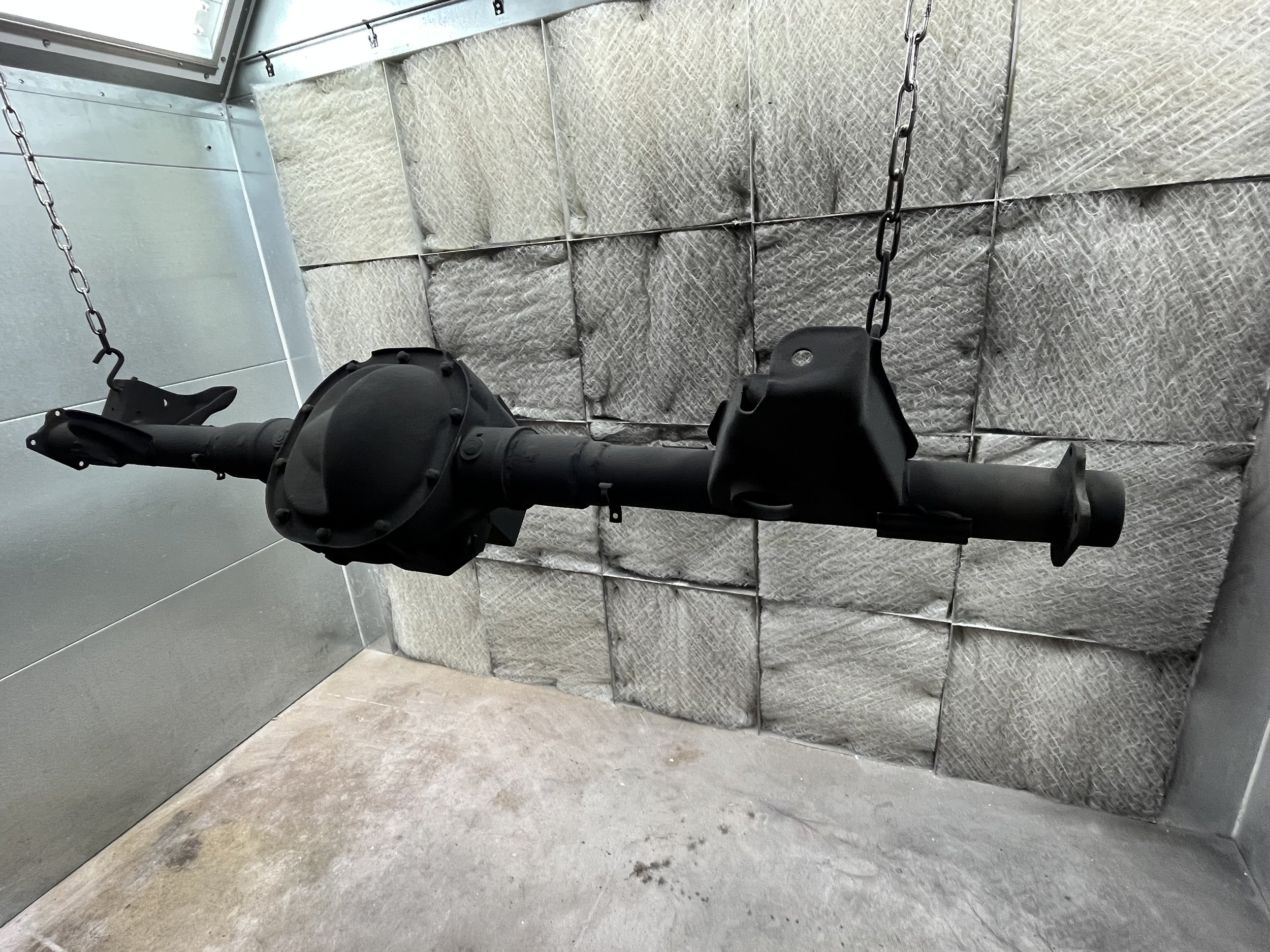

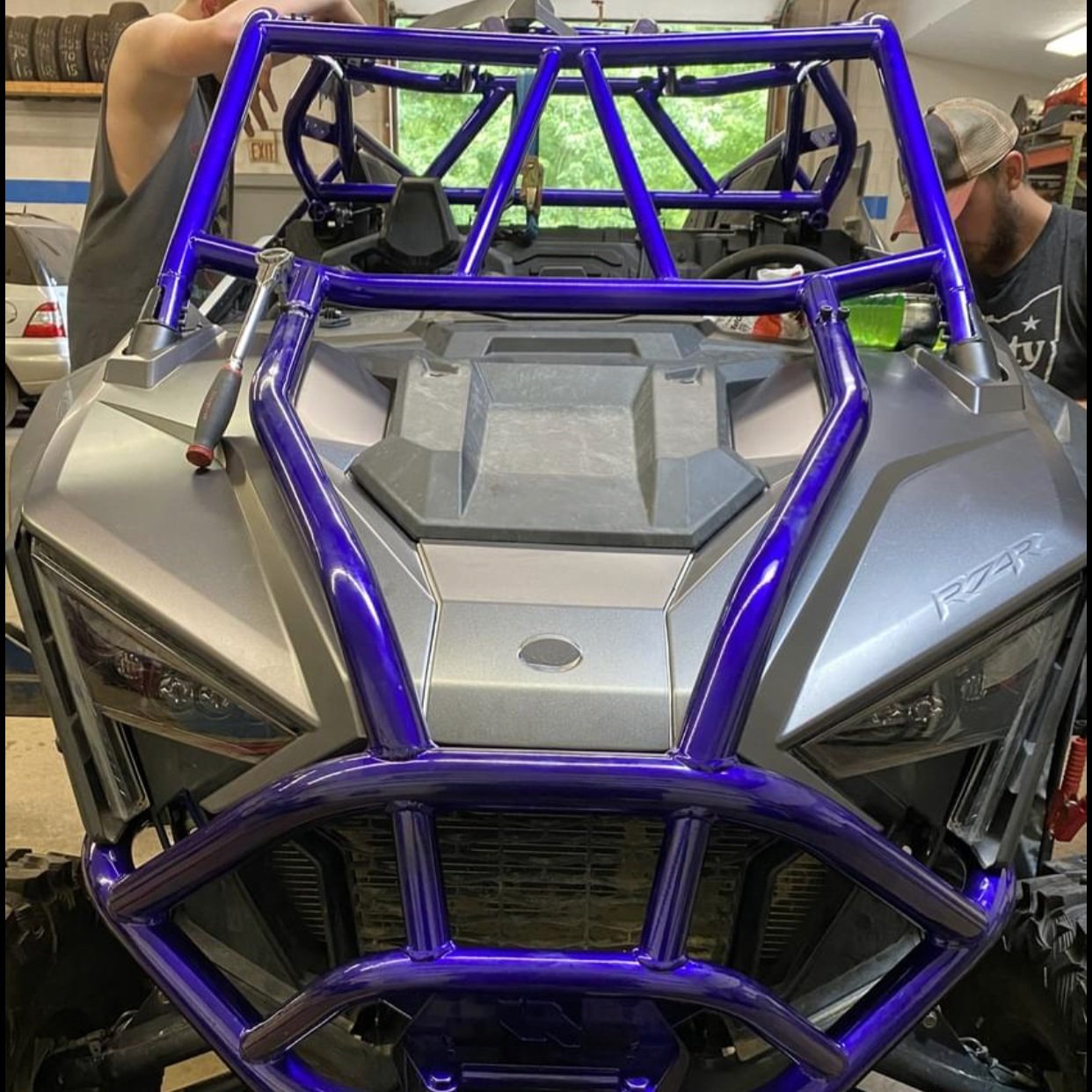

Custom Powder Coating Services

We are a production level facility that processes thousands of parts each week. We also have a dedicated custom job department totally separate from our production line to facilitate the needs of our customers that just want to get their personal items dipped. Our team of professionals dedicated to custom work have years of experience with production as well as very complex, one-off piece work which enables us to provide accurate results with minimal testing time for a shorter lead time than a large production job. Automotive parts, motorcycles, electronics, household, etc. are some of the types of parts we process each week for our walk in clients. Click here for a free quote or give us a call!

The Powder Coating Process

The powder coating process starts with removal of all dirt, grease, and residue that exists on almost all substrates as it comes into our facility. We take every precaution necessary to ensure proper adhesion for a long lasting product. Once cleaned and degreased, we then media blast or acid etch the surface of the part to ensure proper adhesion as required by the manufacturers requirements. The next step is to apply your specific coating and bake at roughly 400 degress (most powders and substrates). Finally, allow to cool and inspect for quality, adhesion, and adequate coverage. ALL parts are inspected using a MIL thickness gauge before final QC and approval to leave the facility.

Media Blast

Nearly all substrates and parts that enter our facility require an abrasive media blasting process in order to acquire proper adhesion. We have several types of blast media for different substrates that are specific to different alloys and substrate capacities. In the event that existing powder coat is on the part, we first submerge the part in an acid back specifically designed to remove existing or flawed coatings. This acid does not affect the integrity of the alloy or substrate in any way and is eco-friendly.

Clean & Degrease

Once all surfaces are media blasted for proper adhesion, all parts are then thouroughly cleaned with grease and wax remover, and then acetone treated to remove any residue from handling the parts. This is also our time to remove any residual media from the media blasting process.

Apply Powder

Our next step in the process is to apply 2-7 mil thickness coat of powder. Powder coat comes in various types, colors, and textures. TGIC and Polyester powders are most common for both OEM/Commercial as well as custom projects. All powders that we use are un-recycled and virgin products to ensure cross contamination does not exist in

Oven Cure

The final step in the powder coating process is to cure or bake the powder. In this step, the solid powder particles become fluid and adhere to oneanother creating a much more durable coating than any wet paint can provide. Most powders cure at a temperature roughly 400 degrees for roughly 10-15 minutes. Cure times do not start until the substrate surface temperature reaches 400 degrees. After curing, a final QC inspection of the part is done to ensure proper coverage and thickness.

Precision Hydrographics & Coatings Staff is Professionally Trained and Certified

Precision Hydrographics & Coatings employees are factory trained and certified on all aspects of our process to ensure the highest quality control standards are met or exceeded on each project we work on

Our Location:

31 Waterloo Rd,

Mogador, OH 44260

Business Hours:

M-F 7:30 - 5:30

Phone Number:

(330) 426-8113